Precision control for side bending, hot-pipe bending, and light-bulb-powered kilns.

I’ve often been asked about this box, though people usually don’t realize they’re inquiring about it. They’re more interested in what the box controls.

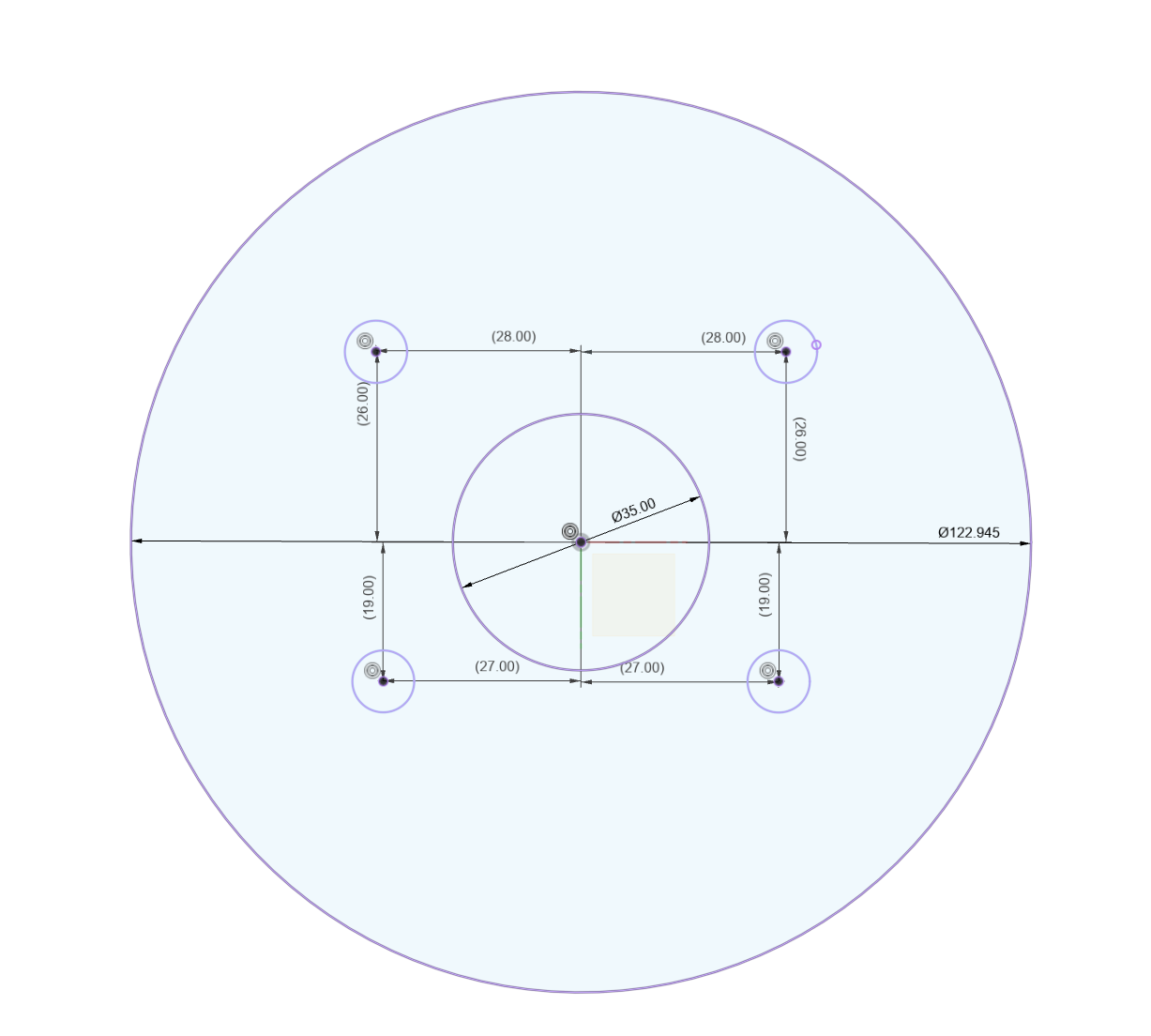

This box is a homemade temperature control unit that I use in my shop in various ways. The primary use is controlling a silicone heating blanket for bending ukulele sides. The setup consists of a sandwich with spring steel, the wood, the heating blanket, and a thermocouple between the wood and the heating blanket. I heat it to around 300°F to bend the wood around a form.

You might see similar controllers on commercial side benders from luthier supply companies, but this box wasn’t initially designed for that purpose. I actually built it for chair-making where it controlled my light bulb kiln—a simple box lined with foil insulation and heated with a 200-watt incandescent bulb. Though I don’t build chairs much anymore, I use this kiln as a filament dryer to dry out TPU flexible filament for 3D printing.

I also use the temperature control unit for my hot pipe bending rig, which is different from most commercial rigs that use a propane torch and steel pipe. I prefer this setup for better temperature control and safety. The rig consists of a steel pipe with a 150-watt incandescent bulb inside. The end of the pipe is plugged with steel wool to prevent heat from radiating out. A thermocouple inside the pipe measures the temperature. I initially used this setup for bending ukulele sides but found it too advanced for my occasional use. Still, it’s a valuable tool in my workshop for tweaking bends and other purposes.

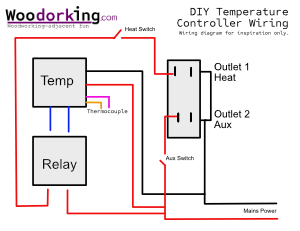

If you’re interested in building a temperature controller, I’ve provided a schematic. Be cautious with electrical projects and ensure proper grounding. If you’re uncomfortable with electrical work, consider using a ready-made solution. I’ll link to some options and resources if you want to explore further.

Feel free to share your experiences or ask questions in the comments. Once you have a temperature controller, you’ll likely discover new uses for it.

File Downloads:

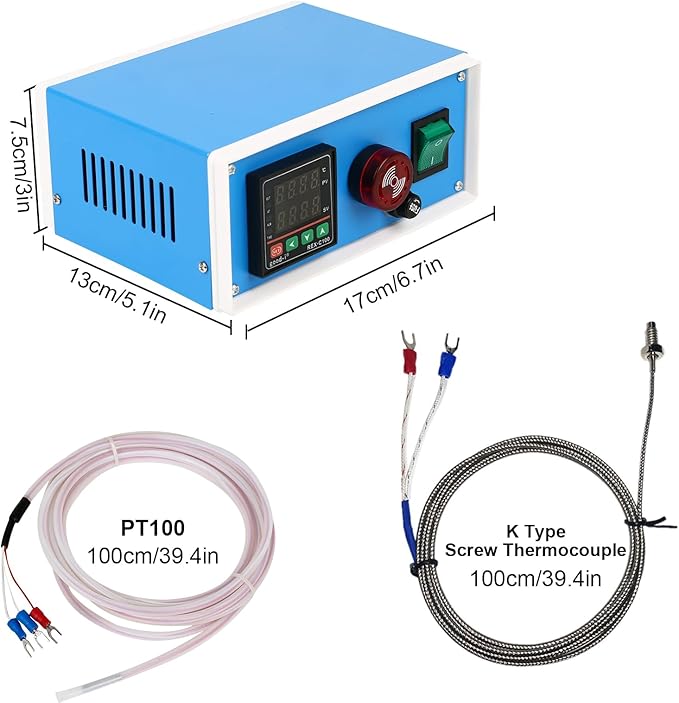

Materials for temperature control unit:

Inkbird AC 100 to 240V ITC-100VH Digital PID Thermostat Temperature Controller

Alternatives:

|

|

I built a heat box for the chairs I’m currently building and used an Inkbird ITC308 freezer thermostat. Seems to be working well.