The Makita RT700C, RT0701C (corded), and XTR01Z (cordless) trim routers are wildly popular among the maker crowd. As a woodworker, I have difficulty declaring it the best trim router on the market. That honor would likely go to the Dewalt DWP611 thanks to the inclusion of LEDs allowing you to see what you’re doing. The Makita likely rose to fame in large part to the CNC crowd. When I first dove into CNC kits over a decade ago there were very few small but mighty routers on the market and the Makita seemed like the default choice for many. At the time of this posting (July of 2024), I’ve been looking at CNC kits again, and many kits (and even some prebuilt) machines are still specked out for the Makita.

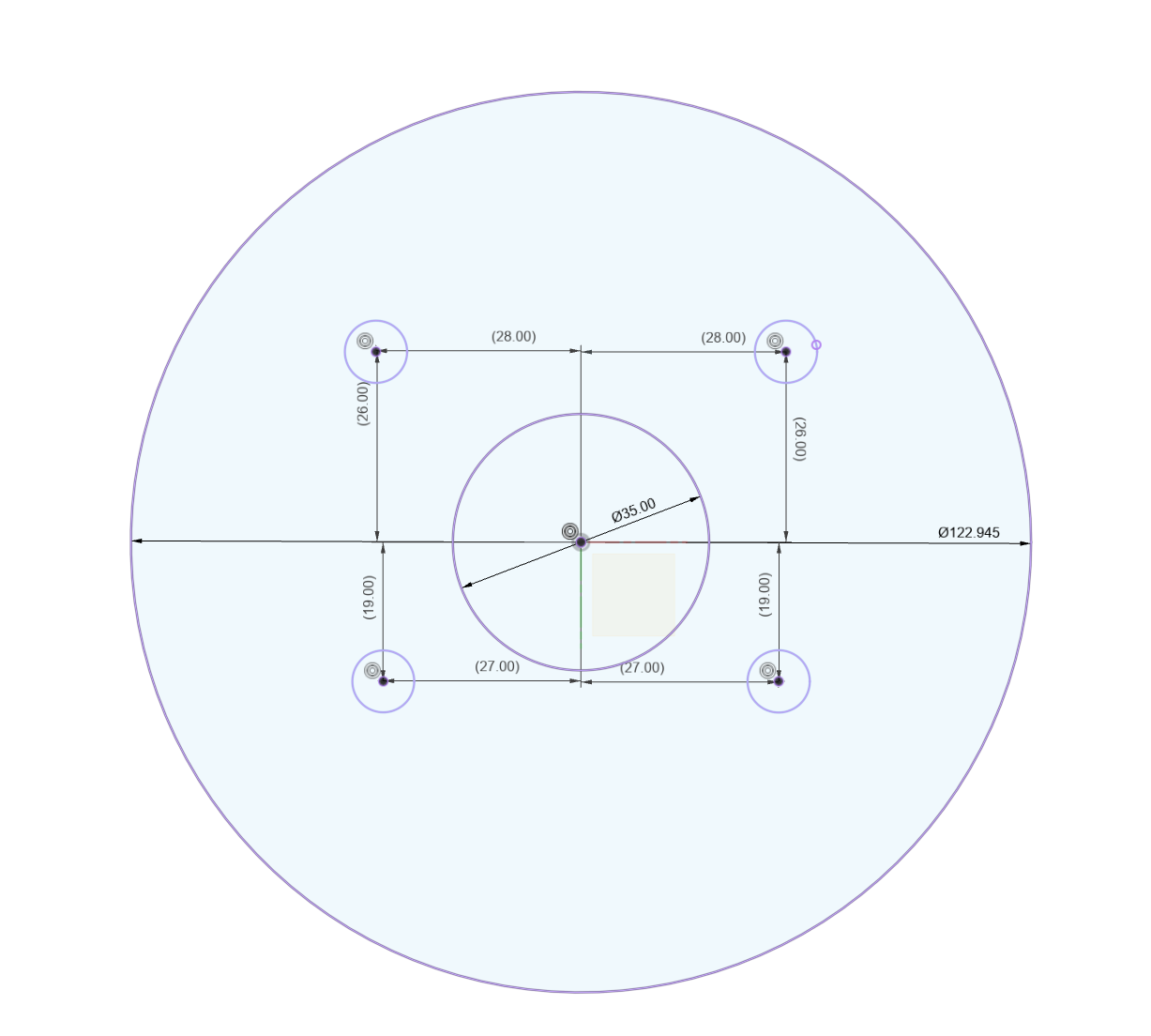

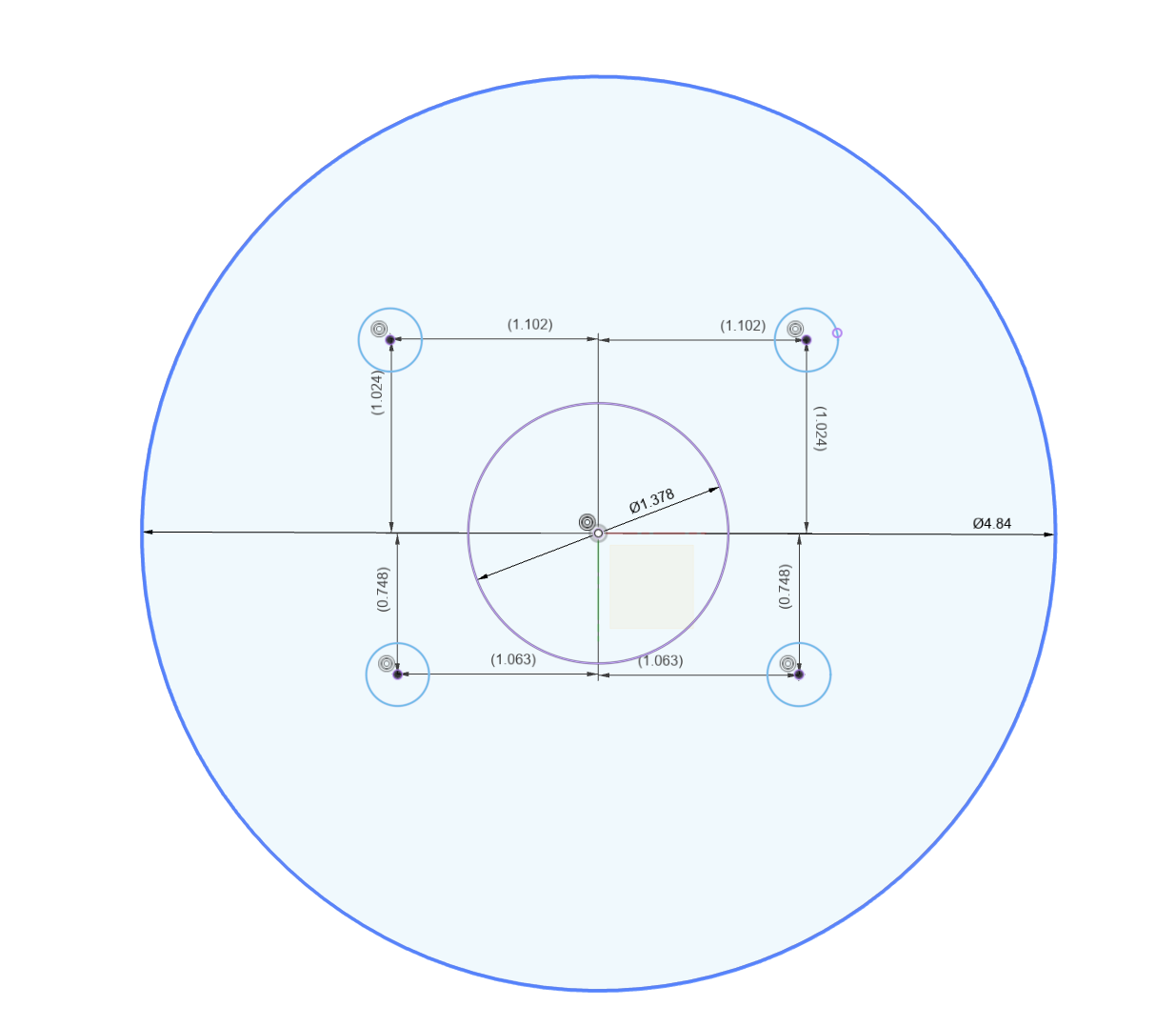

My Makita is still a go-to in my shop. I frequently build bases for it for everything from circle cutting to joinery. Tonight, I sat down at Fusion 360 to model a base for my Makita that will be 3D printed. I measured the hole spacing, created the rest of the somewhat complex model, and hit print. Well… after a half hour or so I decided I should stop the print and double-check my measurements. They were OFF. It was only then that I realized that the hole pattern was not symmetrical and was closer to random than I would have guessed.

A google search turned up very little. To their credit, Lee Valley posted a hole pattern, (probably to work with their trim-router-based router table) but it was missing key dimensions and would be useless to cad. I found a great router plate STL file, imported it into Fusion, and grabbed the dimensions I needed. While I was annoyed I couldn’t find the information easily, I decided to be the change in the world that I’d like to see and decided to post the dimensions for everyone. Have fun and leave a comment if this saved you some frustration!

P.S. Shame on Makita for making the hole pattern so weird.

Addendum: A new search unearthed this wonderful post on Printables that would have saved me time. Credit where credit is due!